Italy’s CMC Marine has grown from a family ‘startup’ to a leading producer of electrically operated stabilisation systems for luxury yachts.

Distinguishing itself through close customer relationships and the ability to deliver highly customised, integrated solutions rather than off-the-shelf products, CMC has carved a significant footprint in the superyacht sector.

“Over the years, we developed a certain reputation for being able to develop solutions for our customer. The product is not a closed box – it’s often the case that the product is a starting point, and we build upon it to create the best solution you need,” says CMC Marine’s vice president, Pietro Cappiello (pictured above).

“On superyachts, you need to adapt to the situation, to what you find on board, to what the needs are for an individual client.”

Cappiello explains that to work successfully in the superyacht and luxury yacht segment, CMC always has to be investing because they have to offer something new.

“Imagine spending all that money on a new superyacht – you want the latest technology onboard and cutting edge. Otherwise, why invest so much money to have the same thing that the other guy has already found.

“You wouldn’t buy a Ferrari and have the same radio as you had in your car ten years ago, would you?”

The company released its Energy Recovery System, engineered for consumption reduction and efficiency optimisation, and developed in collaboration with its suppliers.

“The energy recovery system was born from clients wanting to either reduce the size of the generator to reduce consumption,” says Cappiello.

The technology, inspired by the KERS (kinetic energy recovery system) originally created for Formula 1, captures the energy generated during the braking phase of the stabilising fin function, which is then reused during acceleration. The result is a significant reduction in the peak power output demanded from the generators and up to a 30 per cent reduction in overall energy consumption, while maintaining stabilising performance even at zero speed. This means the fins can operate with only one generator running, reducing the associated noise, vibration, and emissions.

“It’s not like we phoned Ferrari and adopted it [KERS], but the tech has been in Formula one over a decade ago and it’s a trickledown. And we see this kind of technology in our hybrid cars on the street that recover energy when a driver is breaking. So the analogy is really helpful when explaining to customers because they can understand immediately as they have seen it in their cars.”

Don’t reinvent – the key is to collaborate with partners

This process of ‘borrowing’ from adjacent industries forms part of the ongoing ethos of CMC Marine.

Cappiello says that rather than inventing a system from the ground up every time, CMC often adopts best-in-class tech from partners. This philosophy accelerates product development and ensures reliability.

“So rather than redesigning the electrical motor, redesigning the power electronics, CMC likes to approach the market to see what already exists, what we can utilise, tweak and adapt for your solution,” adds Cappiello.

The company has worked with Mitsubishi on several projects including its DC Hi Voltage configuration, which makes CMC’s stabilisation and thruster systems compatible with high-voltage DC power. The innovation is particularly suited to hybrid yachts and other vessels equipped with battery packs and DC-bus systems, in line with the marine industry’s move toward electrification.

Family owned company aids flexibility in today’s market

CMC Marine was founded in 2005 by Pietro’s father, Alessandro Cappiello. In 2008, Alessandro launched the Stabilis Electra system, becoming the first company in the world to patent and market a fully electric stabiliser fin system.

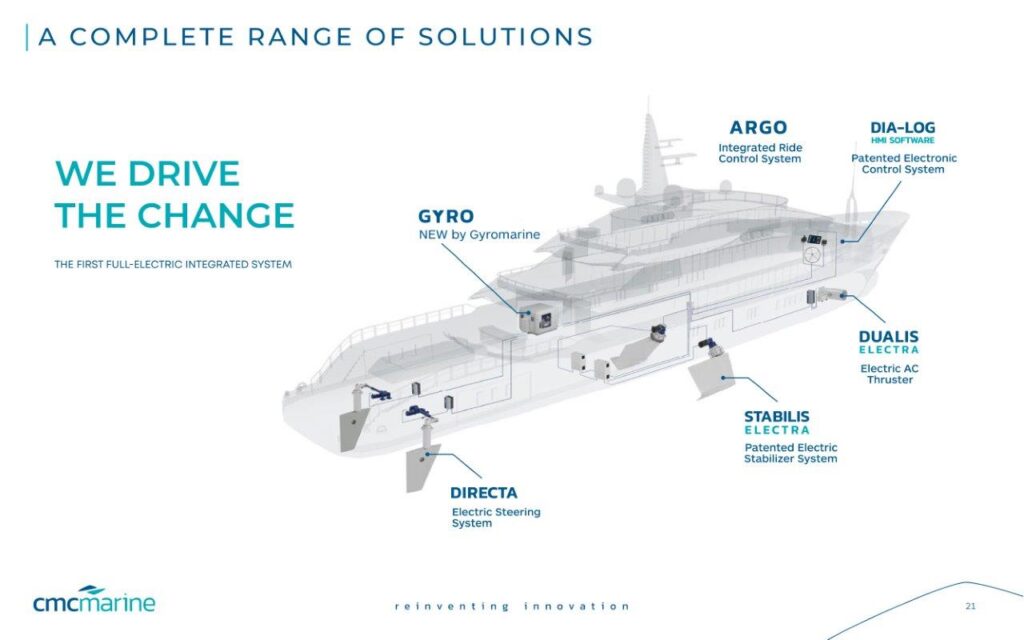

Today, the Italian company is a leading supplier for yachts and superyachts, with multiple sites, a strong international presence, and a product portfolio that includes electric stabilisation, thrusters, fully electric steering systems, and helm station integration.

Pietro Cappiello officially joined the company in 2017. “Until 2017, CMC Marine had two partners: my father and a minority shareholder. In 2017, the family bought out the partner’s shares, making the company 100 per cent family-owned,” he says.

“Being a family company helps a lot in being able to take decisions fast. It imbues us with a flexibility to be able to say yes to something that other company or other owners would probably say no to.”

This agility is vital, Cappiello says, particularly in the superyacht market where bespoke solutions are expected.

“If a customer asks for some customisation, you have to say yes. You can’t just say ‘no’ because it costs us money. Because if we did that, they’ll go to the next guys for their solution.”

Since 2017, CMC has ramped up growth, increasing from €10 million in revenue to over €30 million. In 2018, the company opened CMC USA, followed by CMC UK.

The team has introduced electric stabilisation in the sub 20-metre category, and continued to push the envelope at the other end of the market – installing systems on increasingly larger yachts: first 60 metres, then 75, and now approaching 80 metres.

Cappiello explains that the family knowing how the industry works helps CMC maintain a competitive edge, whereas people from outside the sector often lack that embedded knowledge.

“They tend to see these super luxurious, expensive yachts and somewhat understandably think ‘okay, there’s lot of money to make in this market’.

“But in reality, the high cost of a yacht is down to the build costs being so high. You need a lot of manual labour, you have low volume, so everything is expensive.

“If our company was owned by an investor or hedge fund, it would be hard to explain to them that we have to invest money in a particular product despite the return not being immediate.

Cross-brand integration of electronics is the future

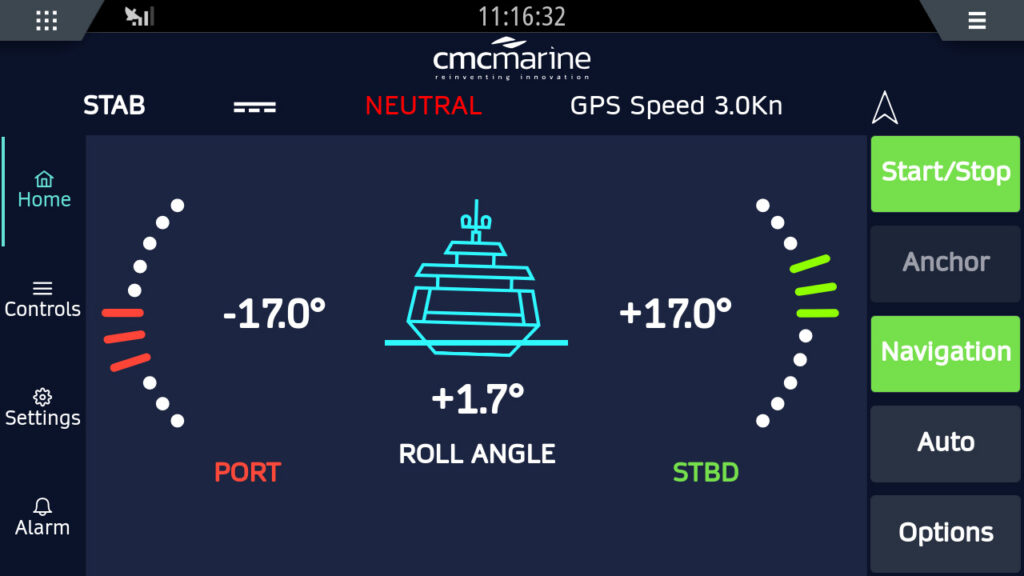

Cappiello says: “In the past – even just a couple of years back – a yacht tended to be like a puzzle of all different systems. All systems were in silo, but now there is an expectation and demand for integrated systems.

“If you are able to give clients a solution that is already integrated or easily integrated with other systems, that’s a huge benefit.

In 2025, CMC announced a new collaboration with Garmin. The Display, Assistance and Logging Interface (DALI) integrates CMC Marine stabilisation and control systems with Garmin multi-function displays (MFD). This follows partnerships formed with Furuno and Raymarine.

In February 2026, the Italian company further strengthened its technological integration strategy with a new agreement with Navico – the group that controls the Simrad, Lowrance and B&G brands and is another leading player in electronic marine instrumentation. These agreements, and others, are designed to offer captains and crew an increasingly comprehensive and interconnected ecosystem of services.

Cappiello explains: “CMC Marine’s goal is to improve both the experience and the safety on board yachts and superyachts, at the same time as making our products increasingly intuitive and integrated with on-board systems. The collaboration with Navico on the integration of its MFDs forms part of this vision: to offer customers, crews and owners even more efficient cruising, in the pursuit of continuous innovation at the service of yachting.”

CMC is also investing heavily in remote diagnostics and support capabilities to provide immediate assistance to yacht owners and captains, a significant value-add in the industry.

Growth and investment strategy

The company opened a 10,000-square-metre production facility in Salerno, Italy, as part of a €10 million investment plan to boost in-house manufacturing of stabilisers and components. Operational since late 2023/early 2024, the site features three industrial sheds, enhancing production efficiency for GRP, carbon fibre, and mechanical parts.

“At some point you say, okay, if we want to grow more, if we want to be more flexible, we need to be able to customise inhouse. Manufacturing inhouse means we are able to deliver more custom solutions for clients, which in the superyacht space is critical,” he says.

Cappiello says that over the last one to two years, CMC has seen strong growth in the 40-metre-plus sector, while experiencing a slowdown in smaller yachts (25–30m).

“Across the marine market the sector has slowed down a lot. Now everyone is waiting to see what happens in the US. Everyone is hoping for or expecting a bit of recovery in that market. But the bigger segment is still going strong and we’re going bigger and bigger in size of yachts,” he says.

He is keen to see how the market fares in two years, towards the end of this current cycle.

Italy’s craftsmanship

Proudly Italian, CMC has built on its heritage. “As many shipyards are in Italy, we have the advantage of proximity and being able to talk the same language. It sounds throwaway, perhaps, but we know how Italians like to work.”

But Cappiello and his father had to change some perceptions outside of Italy, too.

“If its design, style, interior decoration and so on and it’s Italian, there is a preconception it’s elite. And it often is. But then with technical products, there has previously been a preconception that German or Scandinavian are elite. But we’ve proved them wrong. It used to be harder to go and sell to the Dutch shipyards but now we have the references and the reputation. Italians can make the best technical products and have the best style!”

The post CMC Marine’s VP: adopting tech from other industries keeps us agile in superyacht segment appeared first on Marine Industry News.