Miami-based E-Force Marine is introducing a large-scale 3D printing technology for the hull mould of its upcoming electric catamaran.

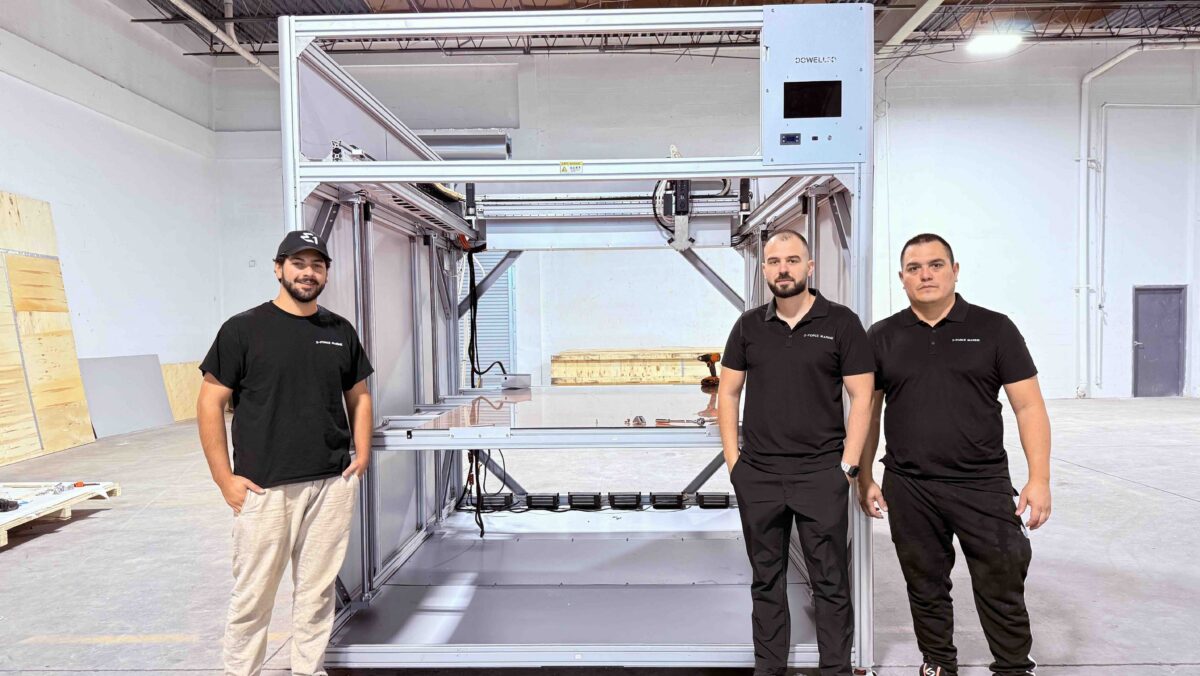

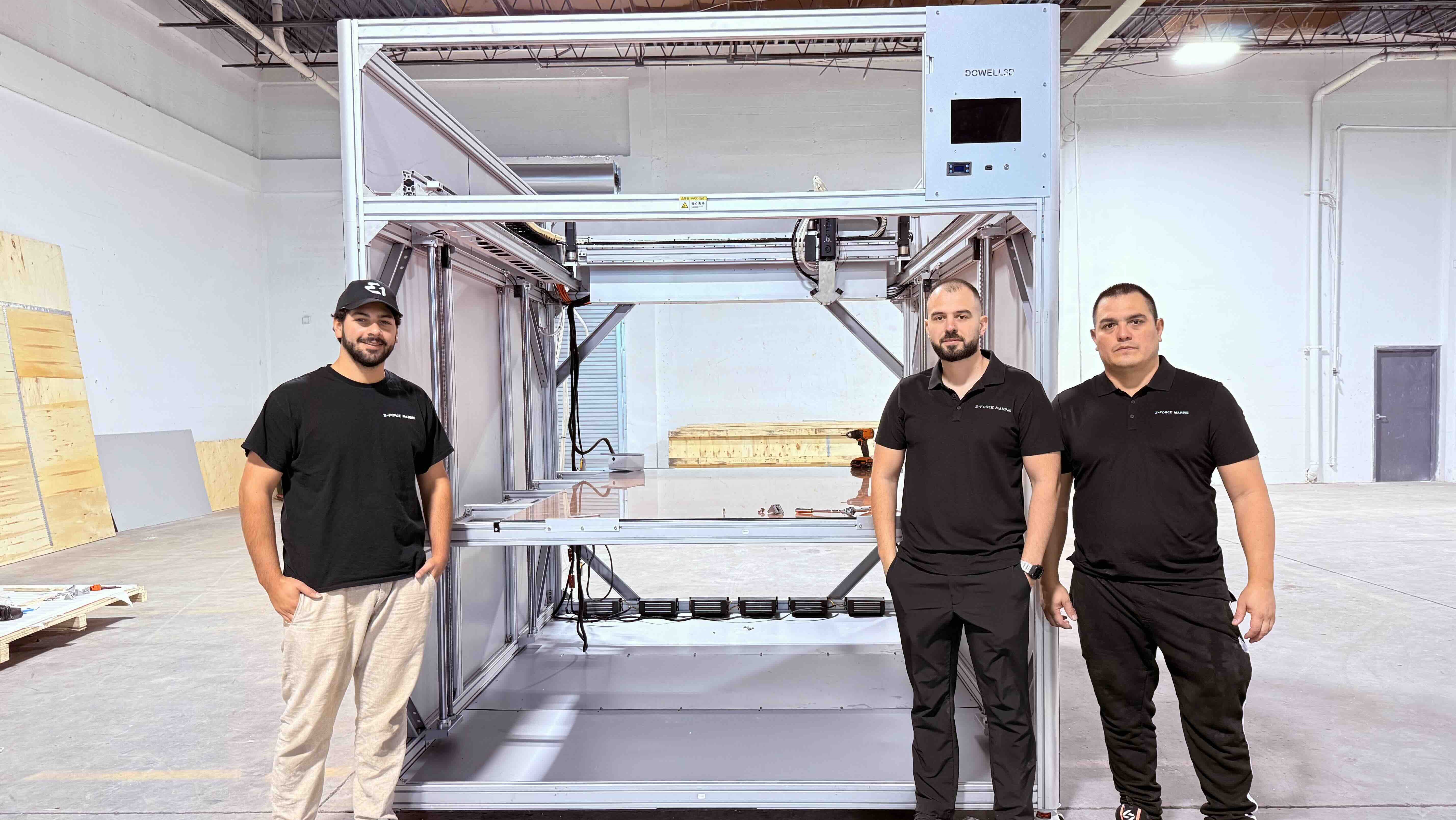

The family owned marine tech firm has invested in an industrial-scale 3D printer, which is capable of producing the catamaran’s hull mould in modular sections. E-Force Marine will showcase its latest progress at the Miami International Boat Show, taking place 11 to 15 February.

E-Force Marine first revealed its catamaran designs in 2025.

The 3D printing technology replaces the traditional, time-consuming plug-and-mould method used by boatbuilders.

The approach is among the first of its kind in South Florida, where experts have highlighted the region’s thriving startup ecosystem, backed by strong investor networks.

Boatbuilding with Large-Scale 3D Printing

Traditional fibreglass boat construction typically requires a full-scale physical ‘plug’ to be built before a mould can be created. According to E-Force Marine, this process is costly, slow, and difficult to modify once complete.

For electric boats, where efficiency, hydrodynamics and weight optimisation are critical, such rigidity can significantly limit innovation.

E-Force Marine’s new approach replaces this step by digitally designing the hull and 3D printing the mould in approximately 1.5-metre sections, which are then assembled to form the full mould. This enables the team to iterate rapidly, refine hull geometry, and test performance-driven changes without restarting the entire tooling process.

The technology has been applied to the company’s latest catamaran design, which features newly developed hull ‘tunnels’ engineered to improve water flow, reduce drag and increase efficiency – a key requirement for achieving long range in electric vessels.

“Boatbuilding hasn’t fundamentally changed in decades,” says Al Haghayegh, CEO at E-Force Marine. “For electric vessels, efficiency is everything, and the ability to fine-tune hull performance quickly is a game-changer. Every small gain in efficiency translates directly into more range, better performance, or lower battery requirements, and that level of iteration simply isn’t possible with traditional tooling.”

Turning proven tech into a flagship electric catamaran

E-Force Marine is positioning its catamaran as a practical, owner-focused electric vessel.

The new catamaran also reflects a strategic evolution for E-Force Marine. After several years developing its technology and focusing on B2B electric drive systems, the company is now prioritising the development of its own inboard electric catamaran as a flagship product.

While electric outboards have gained traction, E-Force Marine believes inboard electric drives are essential for delivering the speed, range and reliability needed to make electric boats truly competitive. The catamaran will be powered by the company’s 100kW electric drive system, which has undergone more than three years of testing.

Prototype construction on the electric catamaran is scheduled to begin later this year, with on-water testing expected within approximately nine months. The company is targeting a full market launch in 2027.

Visitors to the Miami International Boat Show can meet the E-Force Marine team at stand number #MB65L.

The post Electric catamaran innovator invests in 3D printed hull technology appeared first on Marine Industry News.